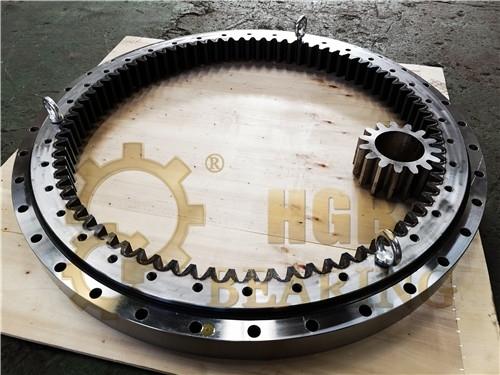

Together with attachment holes in both rings they enable an optimized power transmission with a simple and quick connection between adjacent machine components.

Excavator slew ring grease.

Slewing ring bearings are used in applications for transferring supporting axial radial and moment loads singularly or in combination.

The excavator slewing bearing device is composed of a turntable a slewing bearing and a slewing mechanism the outer ring of the slewing bearing is connect to turntable with high strength bolts it divides three stages forcing the bolts pre tightening inner race with teeth and chassis connected by bolts inner race and outer race has rolling.

Hydraulic oil leak appearing from around the ring gear where cab swivels on the tracks.

Excavator slew ring bearing removed reconditioned and replaced.

Slewing ring bearing installation process lithium grease lubrication.

Slewing ring bearing installation process lithium grease lubrication.

This is only for vertical wear.

And usually having a gear integral with one of the rings.

Close examination reveals that the slew bearing has lost the plot.

Slewing bearings comprise an inner ring and an outer ring one of which usually incorporates a gear.

Slew ring gear leak.

Apply a liberal shot of extreme pressure grease to the fittings around the bearing s circumference at intervals recommended in the operator s manual.

Six steps to save slewing ring bearings.

This old girl presents her self at the workshop with a great deal of free play between the undercarriage and the top of the machine.

Look for grease for leaks out of the bearing bad seal.

Typically slewing ring bearings are used in excavators crane.

More than 96 of slewing ring failure could be avoided by following simple maintenance tips.